(When) is an automated tugger train worthwhile?

Do I have to jump on the train and what does it cost me in terms of time and money?

Experts agree that, in the long-term future, many (intra)logistics transport processes will be automated. Companies are feeling the pressure to optimise processes in order to remain competitive. It is crucial not to let digital transformation in intralogistics pass you by.

STILL is the perfect partner to help you find the right solution at the right time. But this does not mean that automation is always worthwhile or that it needs an immediate response.

At its core, it is not the pros and cons of automation that are key for the company, but rather the way in which internal processes will operate in three or five years' time.

If processes such as transport or loading and unloading are to be automated, the costs, time and effort depend on various factors. These include the starting situation in the company, the technology to be used, the quantity and quality of the available data, and whether the project involves a new build or a retrofit.

The automation market is booming and the technology is dynamic. Rapid developments can mean that recent capital expenditures quickly become obsolete. What is problematic is that there is currently little standardisation in automation, e.g. with regard to the master controller. This means that there is a risk of becoming dependent on a single provider. The team at STILL has been an expert in the industry for 100 years and is continuously developing innovative, contemporary solutions. We have gained valuable experience in the concept preparation and implementation of tugger trains over many years, which we make available for the benefit of our customers.

Requirements analysis

Our offer for the joint preparation of the concept and requirements specification

We answer the following question together with you: What potential for automation can be uncovered in your warehouse and production logistics – and what does your automation system ultimately have to achieve?

Result: an individual requirements specification based on your needs, which you can use for your invitation to tender. The requirements specification is the technical basis for your automation concept.

Precision automation. Every project is tailored to the conditions at the specific company. The effort and financial expense will therefore differ in each case. As a result, we first analyse the local distinguishing features and specific goods to be transported, and then determine the most appropriate number of automated tugger trains.

The investment costs include kitting out the premises with trucks (equipment costs) as well as the project costs that arise from consulting and implementation activities.

Equipment costs include:

- towing trucks and their power supply (e.g. manual battery changing system or automatic battery charging system)

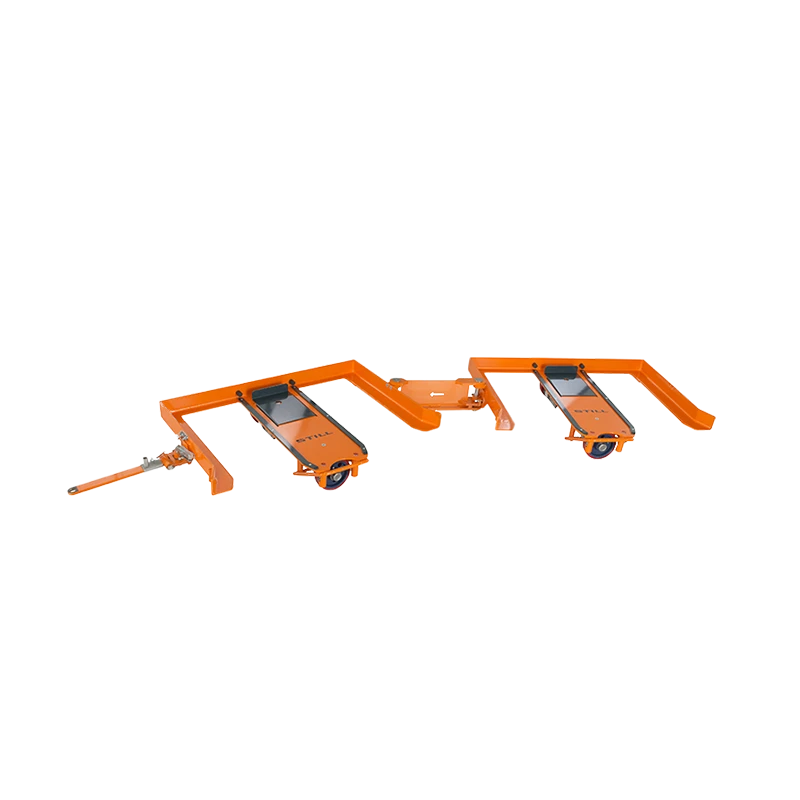

- the tugger train trailers (frames)

- software

- navigation system

Fundamentally speaking, the project implementation costs include:

- concept development

- engineering and layouting

- truck and component manufacture

- software programming and parametrisation

- project management

- truck validation in the factory

- assembly and commissioning

- truck validation by the customer

- CE documentation and training

- product and application software licences

- and transport of the trucks to their place of use.

In summary: Experience has shown that it is not possible to determine a general minimum duration for all the project steps from the initial consultation through to the operational implementation of an automated tugger train; this needs to be considered on an individual basis. The amortisation time depends on several factors, including the number of shifts and the number of trucks to be used or replaced, the degree of automation and the wage costs saved as a result of the automated process steps.

We use our expertise to help you analyse your processes and identify automation potentials in order to set your company up for the future.

Following your request, we would be pleased to send you a free download of our white paper as an introduction to automated tugger trains.

Rückruf vereinbaren

Glossary

Master controller

The master controller controls all of the trucks operating in the system. It helps the operator continuously optimise the operation. It connects a general host system, such as a warehouse control system (WCS) or a warehouse management system (WMS), and the deployed trucks.

Tugger train

Tugger trains are a means of transport for ground-level material transport. They are generally made up of a towing truck and one or more trailers, on which carriers are placed. Both the driving and load handling can be carried out either manually or partly or fully automatically.

Driverless transport systems

Driverless transport systems (DTS) are defined as follows according to VDI Guideline 2510: They consist of various components that have to work together in a precisely controlled and coordinated manner. These include a master controller, equipment for detecting and recording the location and position of the transport trucks, equipment for transmitting data to and from the trucks in the DTS, infrastructure and peripheral equipment (e.g. charging stations).

Dual use

Driverless transport systems with a dual-use function can be used in automatic mode as well as with manual control functions.