Very narrow aisle truck NXV

For narrow aisles, high racking and the highest expectations

- Load capacity 1500 kg

- Rated lift 12850 mm

- Speed 10,5 km/h

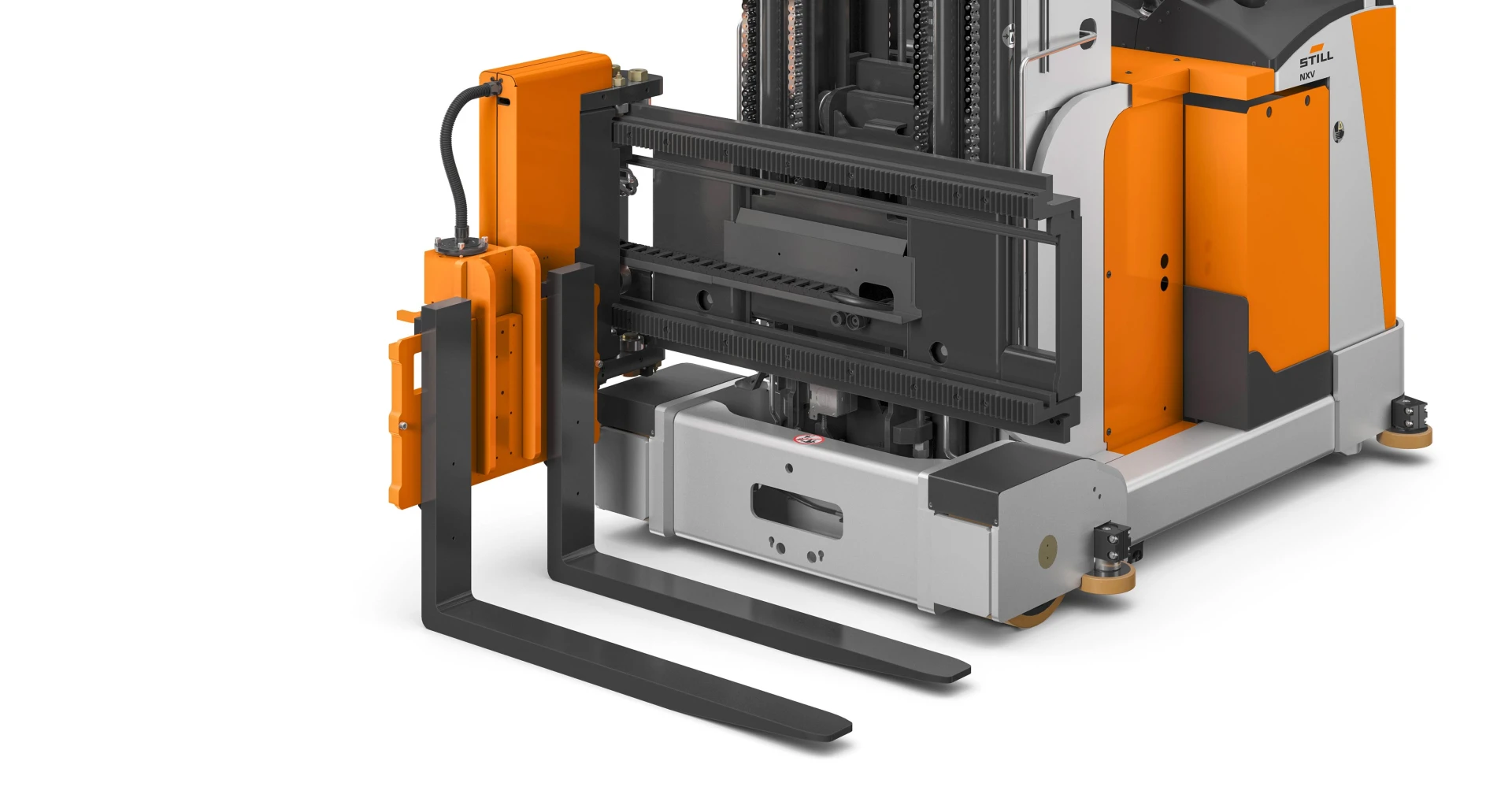

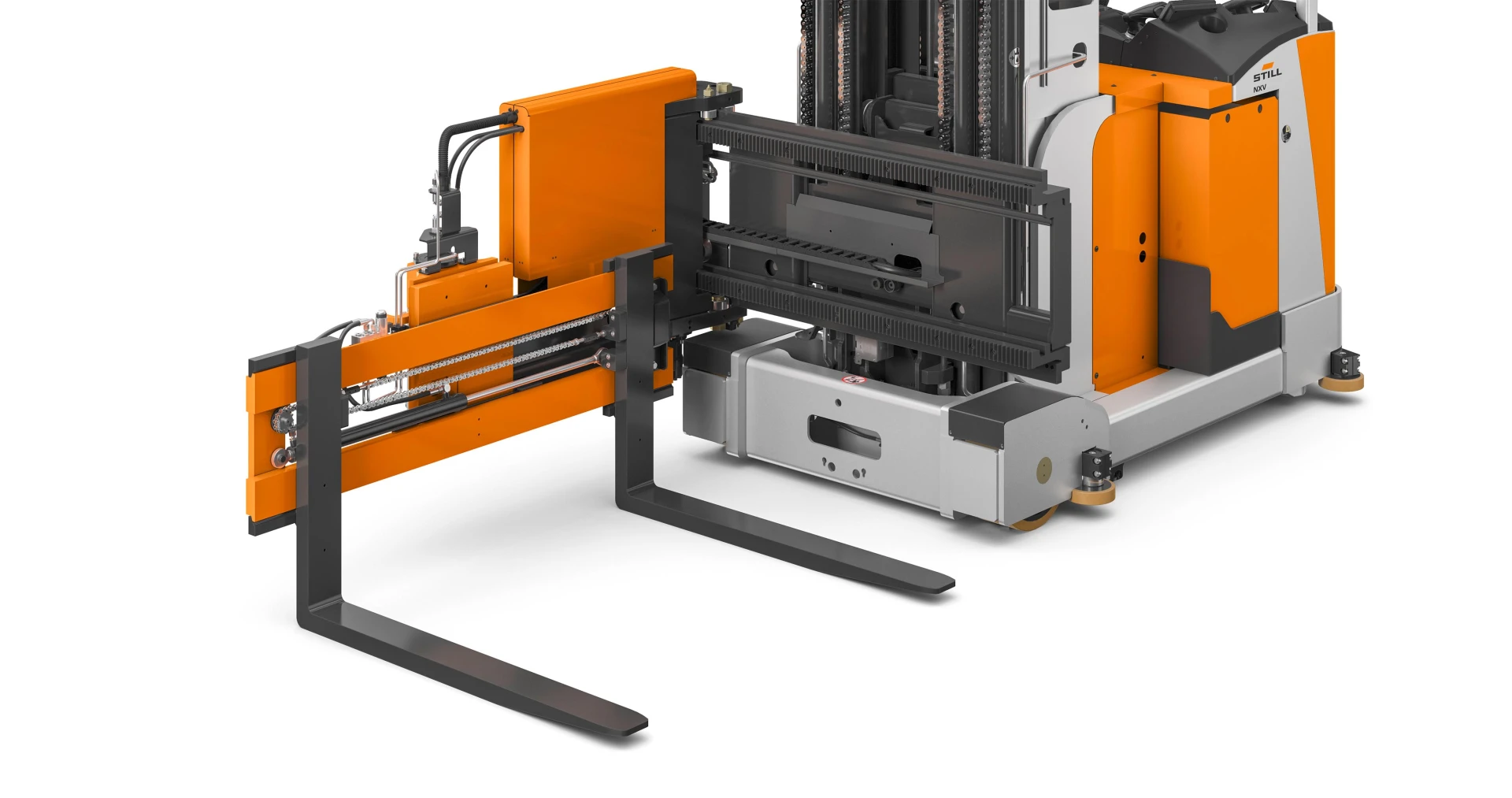

Narrow aisles, high shelves, heavy goods, not much space? If these reflect your requirements, then the answer has exactly three letters: NXV. The Very Narrow Aisle Truck is the ideal partner for efficient space utilisation in small warehouses. Thanks to its compact dimensions and rotating turret head or telescopic fork, it only needs a small amount of space, making it the natural solution for narrow aisles. When it comes to working at height, on the other hand, the more space the better. The NXV provides fast and reliable loading and unloading at heights of up to 13.8 metres. Its robust design, the intelligent operator assistance system OptiSpeed, as well as Active Load Stabilisation (ALS) facilitate the safe and fast handling of goods weighing up to 1,500 kilos at great height. With ALS, it is also possible to increase the handling capacity by up to 5 percent and the system automatically ensures even storage depths. Optional positioning aids, such as the cross line laser between the forks or the camera systems, assist the operator in precisely positioning the load.

The NXV offers operators the best in comfort and ergonomics. It is fitted as standard with the sensitive Joystick 4Plus, which guarantees easy, fatigue-free and user-friendly operation of the truck. The lifting, shifting and turret functions, as well as the direction of travel, can all be operated single-handedly without having to reach around. With numerous individually configurable ‘favourite’ keys, operators can also adjust the workstation to suit their own requirements and personal preferences. Thanks to the large colour display on the STILL Easy Control panel, all the relevant vehicle information is also available in compact form in the operator’s field of vision.

Powerful and robust:

load capacity of up to 1.5 t with a lifting height of up to 13.8 metres

Efficient warehouse utilisation

thanks to safe load handling at great heights and excellent handling capacity thanks to intelligent assistance systems

Ergonomic workstation

with innovative Joystick 4Plus, STILL Easy Control and numerous safety features.

The "Simply Efficent" factors: Performance attributes as a measure of economic efficiency

Simply easy

Easy load handling with one hand:

ergonomic, precise and user- friendly control with the innovative Joystick 4Plus

All relevant vehicle information

at a glance with STILL Easy Control

Easy to adjust:

user-based operating settings with individually configurable favourite keys

Fast and easy battery charging,

and opportunity charging for the lithium-ion version

Simply powerful

High storage density and safe handling,

even with heavy loads (up to 1.5 t) and when working at great heights

Maximum space utilisation

thanks to storage heights of up to 13.8 metres with main and auxiliary lift

Best performance and handling capacity

thanks to OptiSpeed – the intelligent assistance system

Maximum handling performance

at great heights with Active Load Stabilisation (ALS)

Simply safe

Maximum safety for operator and surroundings

thanks to the intelligent operator assistance system iGo pilot safety with automatic speed adjustment, lifting override, aisle departure assistant, and many more

Optimum visibility:

Safety Light ensures that the vehicle is already visible before exiting the aisle

Safe, fast operation and maximum handling capacity

thanks to camera systems and positioning aids such as the cross line laser

Simply flexible

Custom-made forklift trucks,

manufactured in a modular design according to the customer’s specific requirements

Flexible range of applications for different loads and warehouse conditions

thanks to optional push over function

Simply connected

Safe and efficient:

automated bay approach with the aid of iGo pilot navigation

Concisely informed:

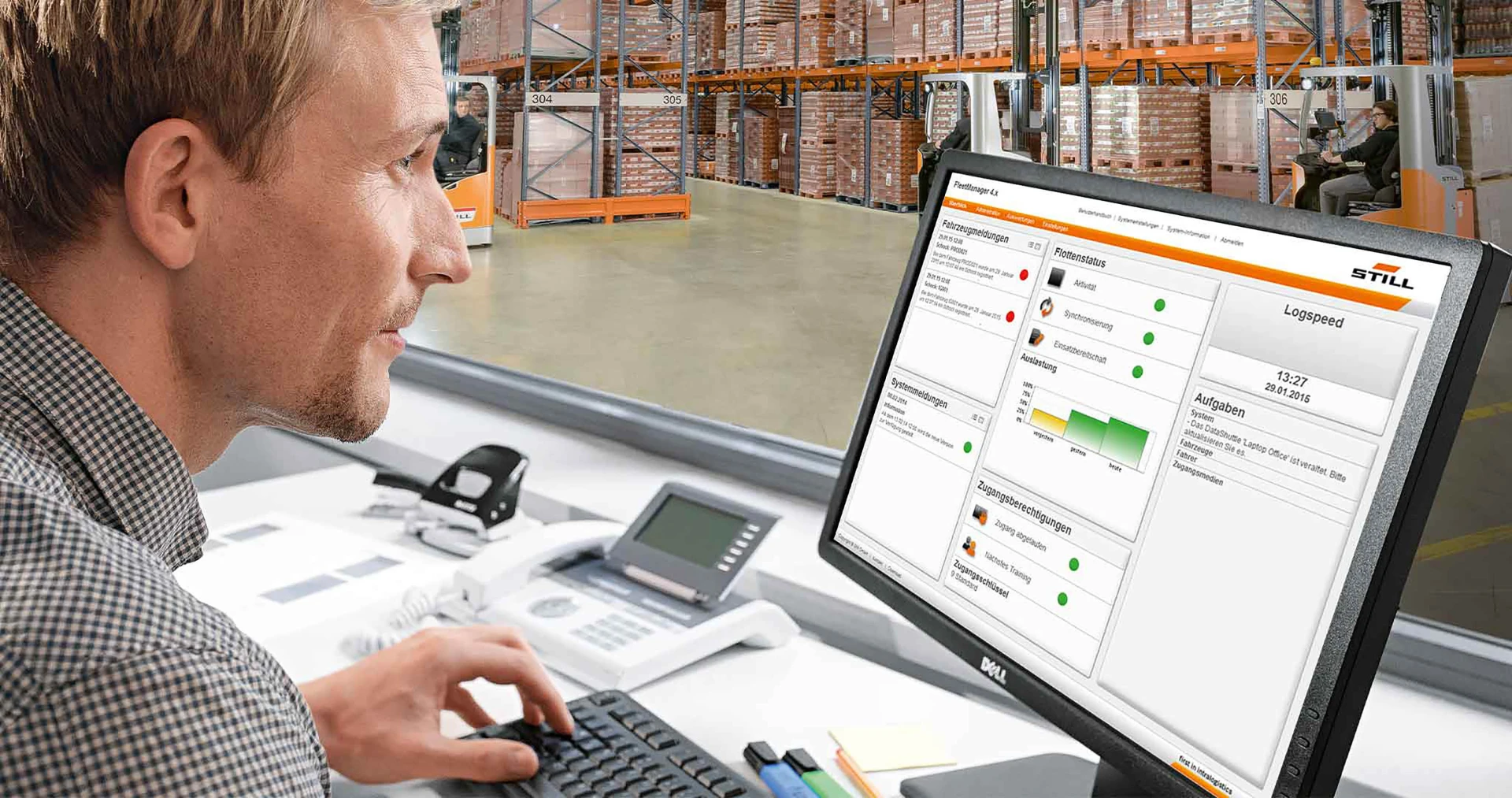

all the relevant vehicle information is contained in the powerful and innovative web application STILL neXXt fleet

Optimum work safety and reliable operator assignment

with the STILL FleetManager 4.x

Optimisation of the goods flow

thanks to easy integration into the warehouse management system (WMS) with the iGo pilot navigation interface

STILL Li-Ion Technology inside

The perfectly harmonised power system for reducing operating costs and increased truck availability.

More about STILL Li-Ion TechnologyEquipment options

Sharpening all senses: we can support you with our wide range of smart driver assistance systems and functions which will make your day-to-day work significantly easier. You will be able to drive in a safer, more comfortable, efficient and fatigue-free manner – in every driving situation.

The visual warning system for fewer accidents

The blue warning light, STILL SafetyLight 4plus, significantly increases work safety in areas which are confusing or full of bends. The blue light spots are projected approx. 5 m in front of and behind the truck and warn people about the approaching truck to prevent impending collisions.

Six in one sweep

Optimised braking paths: at the end of the aisle, the forklift truck decelerates gently in relation to the speed and lifting height, which increases handling capacity.

Automatic speed adjustment: in defined zones, speed adjustments can be set automatically based on the ground conditions.

Height limitation: The adjustable height limitation enables optimum use of the space below the roof for different hall heights.

Collision prevention: known obstacles can be defined. The driver does not need to memorise all particularities of the system and can concentrate on their work.

Aisle departure assistant: steering can be blocked for a defined stretch, e.g. when departing the aisle in order to prevent collisions.

Position selection: selection enables targeted movement into defined, often-used positions such as at transfer points.

With the mobile personal protection system from STILL, you are on the safe side when it comes to protecting people in narrow aisles. Sensitive safety scanners on the drive and load sides of the VNA truck monitor the route and reliably detect people in the aisle. Thanks to the latest scanner technology, the STILL PPS meets all legal requirements for occupational health and safety and workplace regulations - in a lean and efficient way.

Early braking in narrow aisle operation

The Predictive Braking System detects obstacles in narrow aisles at an early stage and initiates automatic responses depending on the situation – for greater safety in tight spaces.

- Detection of static obstacles up to 8 meters away

- Definition of warning and protection zones with individual configuration

- Automatic responses: warning signal, speed reduction, or vehicle stop

- Easy integration into new or existing vehicles

- Ideal for narrow aisle warehouses with high traffic density and limited visibility

With the help of the optional LED lift height sensor (standard on the FM-X), the lift height display ensures maximum precision from the very first millimetre. This means that operators always know the height of the fork tips and can navigate precisely to avoid touching the rack when picking up the pallet. The system works with a repeatability of less than +/- 5 mm and the lift height is permanently shown to the drivers on the display.

Learn moreUnique around the world: active load stabilisation in narrow aisle operations

Save time during storage and retrieval: heavy loads cause shaking in the MX-X lift heights. This results in a waiting period until the shaking subsides. The optional ASL counteracts this with additional lifting to reduce the shaking and waiting time. It makes work considerably more pleasant and increases the handling capacity by up to 5%. The system enables quick and safe transport movements which are optimally adapted to the lift height and load.

Navigation support for the driver

The system optimises the approach to the destination by stopping forks automatically at the horizontal and vertical target position. The positioning is worked out by means of distance measuring and comparison with the current position (by RFID transponders or barcodes). OptiSpeed 4.0 differentiates between loading, unloading and order picking at the target position, and adjusts the lifting height of the fork automatically.

Easy to use: manual input of the storage location or retrieval from the warehouse management system; operation at just a push of the drive lever.

High productivity: the truck takes the optimal route to its destination – regardless of the operator’s experience and knowledge.

High precision: the truck moves to the exact position of the pallet – fork movements outside the target are not possible, thus avoiding incorrect storage and retrieval.

Learn moreMaximum handling capacity: STILL OptiSpeed

Comprehensive hardware and software assistance systems which optimise the movements of the equipment regardless of the load. This significantly increases your handling capacity.

With load detection and intelligent load capacity chart for increased handling capacity.

Maximum handling capacity: STILL OptiSpeed

Comprehensive hardware and software assistance systems which optimise the movements of the equipment regardless of the load. This significantly increases your handling capacity.

The system combines the advantages of OptiSpeed 3.1 with a weight sensor: in addition to the visual and acoustic signals when specific limit values are reached, a travel and lift stop is triggered when the permissible load weight is exceeded.

In addition, it calculates ideal transport movements and optimises them based on the lifting height and load.

This enables higher speeds on empty runs or when loading and picking.

Forks up, speed down:

More safety, less product breakage and ensuring proper vehicle use - these are the benefits offered by the Speed Reduction assistance system when the fork carriage is raised. As soon as the forks reach a height of 500 mm (or another defined threshold), the speed of the vehicle is automatically reduced. Even if a driver forgets that he should not drive with the load raised, the assistance system slows him down, guaranteeing safe handling of the load and vehicle.

Learn more|

Model

|

Maximum capacity (kg)

|

Maximum reach height (mm)

|

Travel speed (km/h)

|

Battery voltage (V)

|

|---|---|---|---|---|

| NXV | 1.500 | 15.041 | 10.5 | 48 |

Downloads

The document provided for download is the updated version of the operating instructions for the standard truck. It does not include descriptions of customer options (Customer Option). For a concrete truck, please request the respective specific manual according to the serial number and the year of production from the STILL spare parts service.

We are there for you.

Do you have any questions or would you like personal advice?

Then you've come to the right place. Our team of experts will take care of your request - individually and quickly.

Call a consultant

We are there for you – Monday to Friday between 8 a.m. and 6 p.m

Use the contact form

Write to us – we will get back to you within 24 hours