Racking Systems Drive-in and drive-through racking

Store deep and save space

- Compact storage for good utilisation of space

- Safe storage of goods sensitive to pressure

- Ideal to store large quantities of identical products

- Very good overview of large batches

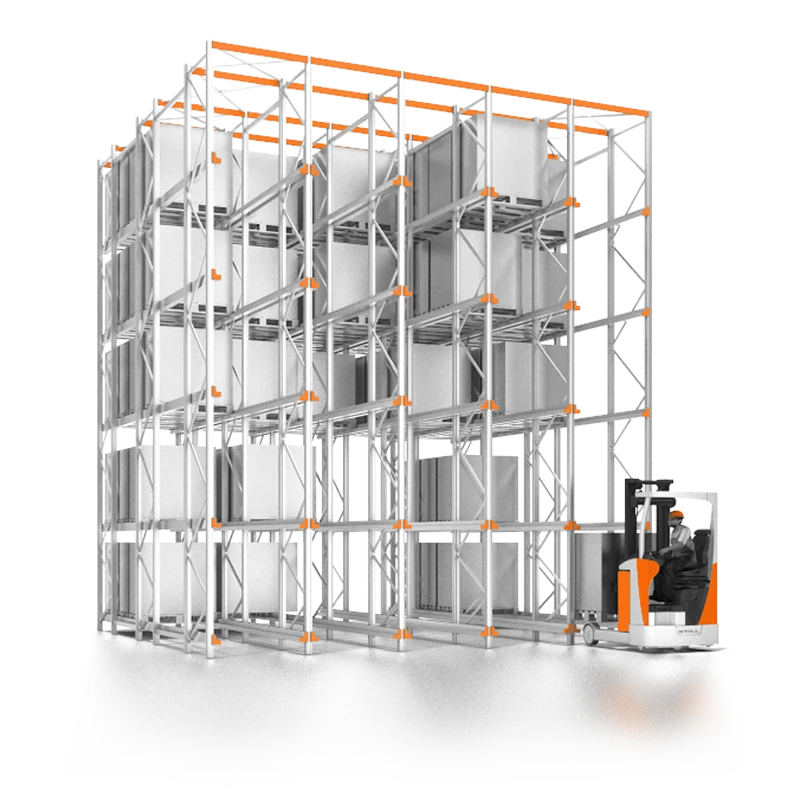

You mainly want to store a large number of identical products in a compact way in your warehouse? Then you should look at the economic STILL drive-in and drive-through racks. Thanks to its flexible design, this type of rack offers outstandingly efficient use of space in the warehouse. If the racks are designed as drive-in racks, materials are stored and retrieved from one face of the rack.

This storage system is ideal for storing several pallets of goods behind one another. The rack is designed to allow industrial trucks to move inside the rack channels to store or retrieve pallets. This type of storage is ideal for goods sensitive to pressure or for warehouses that store seasonal goods as these products usually remain in the channels for a long time. As standard, drive-in racks follow the LiFo principle (Last in, First out). It is also possible to operate drive-through racks by FiFo (First in, First out).

Drive-in and drive-through racks allow the warehouse truck to drive into the rack to stack or destack pallets. The pallets are placed behind each other and they can be stacked in several levels. Normally the pallets will be stored for a long period in the channels of the rack. To drive the truck safely inside the rack, guide rails are mounted to the floor.

The design of the support rails is important for proper functioning of the rack system as the pallets are stored on them. It is important that the distance between the rail supports is wide enough to allow the industrial truck to move inside the rack and place the pallet securely on the rail support. In the standard version, the rail supports are bolted to hooked consoles, which connect the support rails to the frames.

Rack supports

The rack supports are made of special steel profiles and are fixed components of the proven STILL drive-in and drive-through racks. Two supports are bolted to the level profiles to form a column. For better stability, the rack supports are firmly fixed to the floor. Distance pieces connect the individual columns to each other.

Horizontal cross bracings and longitudinal beams

The columns of the drive-in and drive-through racks are connected lengthwise by longitudinal beams which add additional stability to the rack.

Vertical cross beams

Vertical cross beams provide the system with the necessary stability.

Support rail

The pallets are stored on the support rails which are attached to the columns by consoles. The height of each level can be individually adjusted in steps of 50 mm. Wide carrying faces and funneled side walls make sure the pallets are safely positioned.

Collision guard

To increase industrial safety, the well-visible collision guards protect the columns. In case of damage, the collision guards can be easily replaced.

Floor rail

The floor rail protects the frames when the trucks move inside the channel. On request, the floor rail can be omitted in short aisles, or only the first column can be protected by the rail. We recommend using the rail along the whole channel.

Drive-in assistant for the support rail

This assistant protects the pallet and the support rail when the truck enters the channel. It also facilitates correct entrance into the aisle with a lifted pallet. For the truck driver, it is not always easy to see whether the bottom edge of the pallet is already above the carrying face of the rail.

The picture shows the storage and retrieval sequence of drive-in racks that are operated from one end. The goods are stored from bottom to top and then from back to front. Retrieval is carried out in reverse order. The LiFo principle (Last in, First out) is applied to storage and retrieval.

Drive-in racks operated from both ends follow the same storage and retrieval procedure as drive-in racks operated from one end. The only difference: They consist of two drive-in racks, the back sides of which point towards one another.

In drive-through racks, loads are stored on one end and retrieved from the other end of the rack. Drive-through racks therefore follow the FiFo principle (First in, First out).

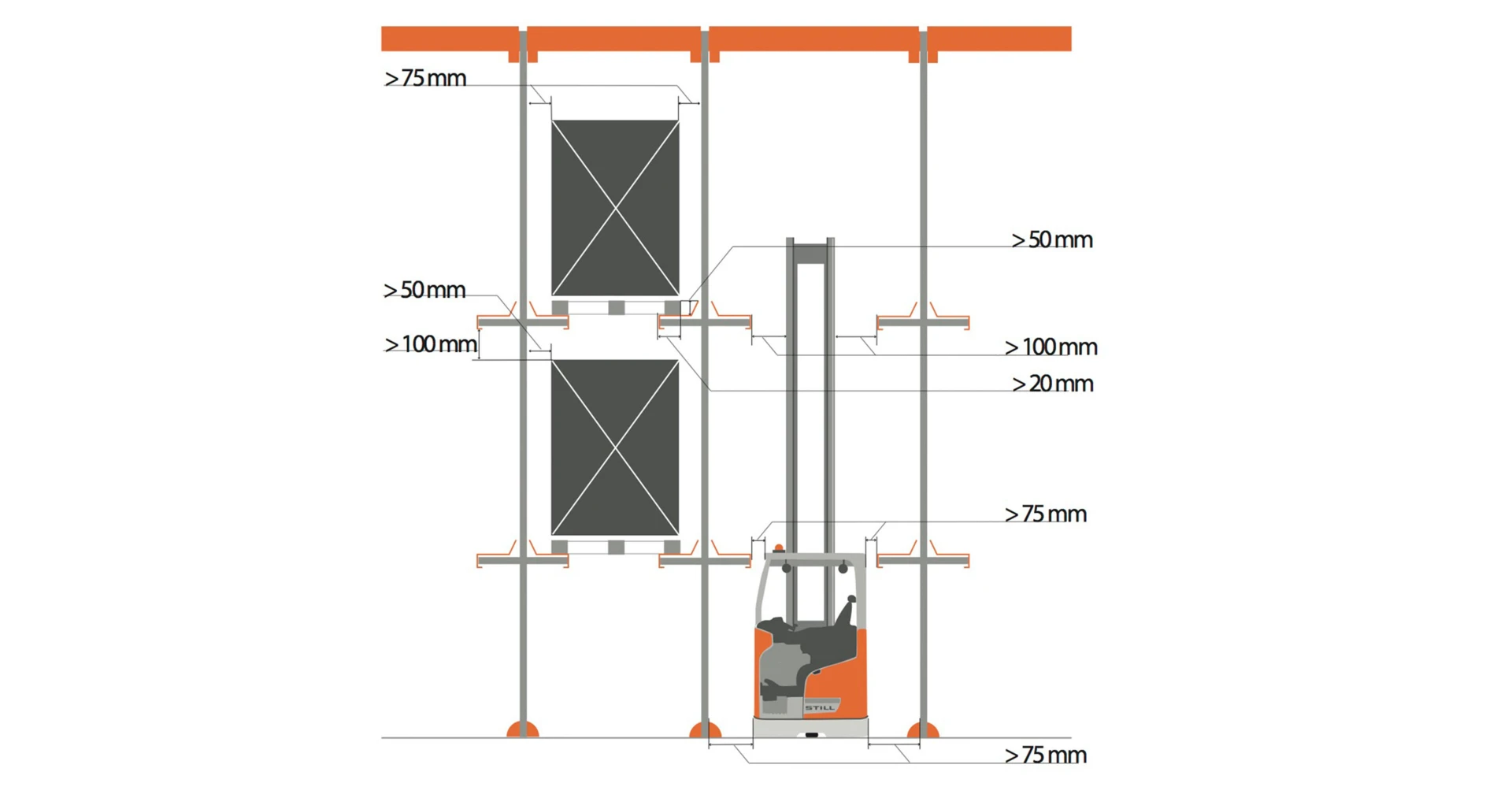

Distances

When planning the rack, FEM requirements with respect to the mandatory distances between the rack frames and the pallets as well as the truck must be adhered to.

A warehouse planned for efficiency guarantees high economic feasibility. Benefit from the professional consultation with our STILL experts right from the start of warehouse planning. Before you make a buying decision, we assist you in every aspect – from checking your warehouse design to discussing the planned workflows. There are many reasons why you should decide for STILL when buying a drive-in and drive-through rack:

- Many years of expertise: Close to our customers for more than 95 years.

- Partnership that you can rely on.

- Holistic premium concept – from consultation to service.

- Always close to you: 14 branches, 37 rental branches & 800 service technicians in Germany alone.

- A trained installation team ensures proper assembly of your drive-in and drive-through racks.