Racking Systems Mobile racks

System for maximum space utilisation

- Maximum usage of available warehouse space – space-saving of up to 80% compared to conventional racks.

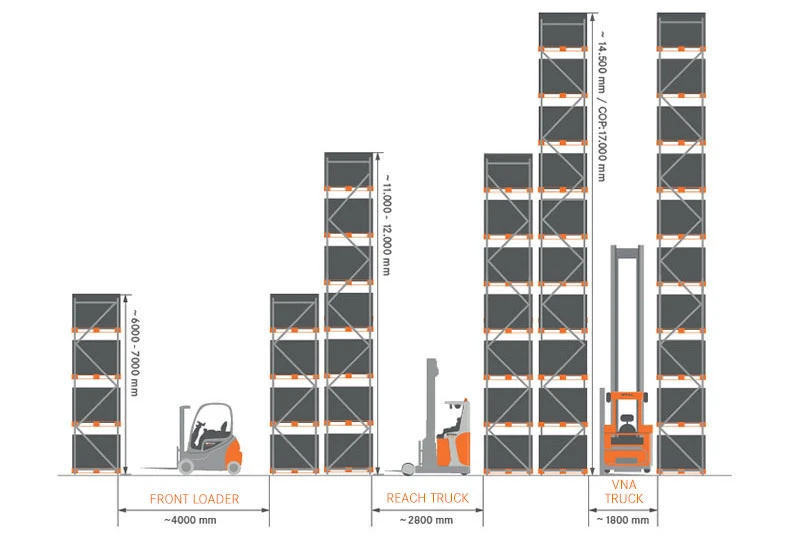

- Working aisles are adapted to the truck and the process - if required, more than one working aisle can be planned or several narrow aisles for order picking can be opened

- The system can be installed in several phases to gradually increase warehouse capacity

- Access to every storage area in the opened working aisle

- Short distances

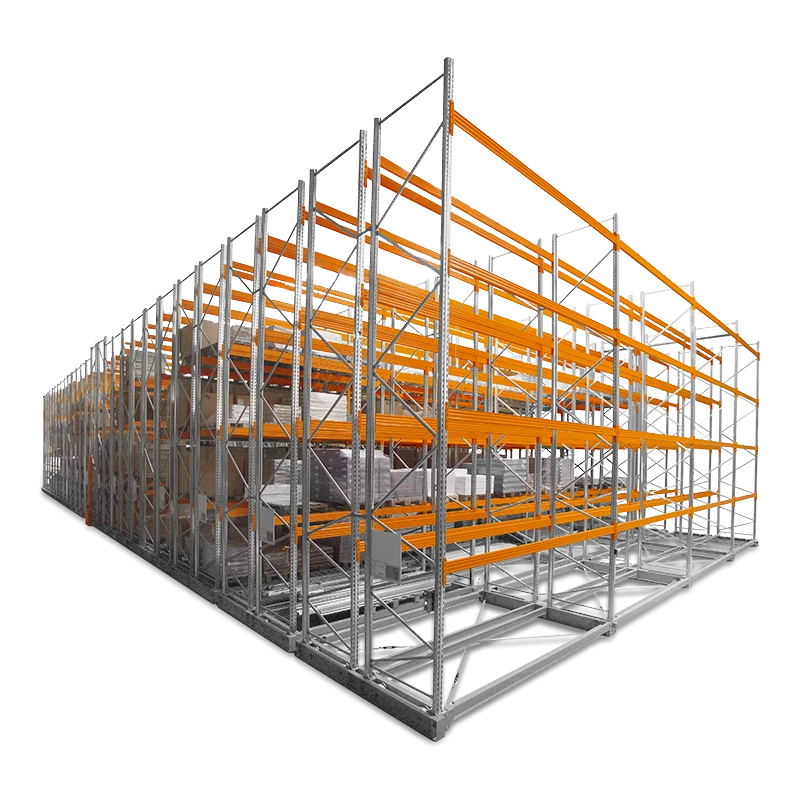

Do you want to store your goods as space-saving as possible? Take a look at the mobile racks from STILL. This racking system only requires space for a single working aisle for storage and retrieval – the rest of the warehouse can be completely used for storage.

Highlight of mobile racks: The aisles of this system are mounted on carriages that are moved by electric motors. The STILL mobile rack allows space-saving storage of goods, while each storage location can be directly accessed by moving the rack.

As there is only one working aisle, the available storage space can be optimally used. For example, this is a benefit for cold stores and freezers. Compared to other racking systems, much more goods can be stored on a given floor space. The width of the working aisle in a STILL mobile rack can be adapted to the industrial trucks deployed.

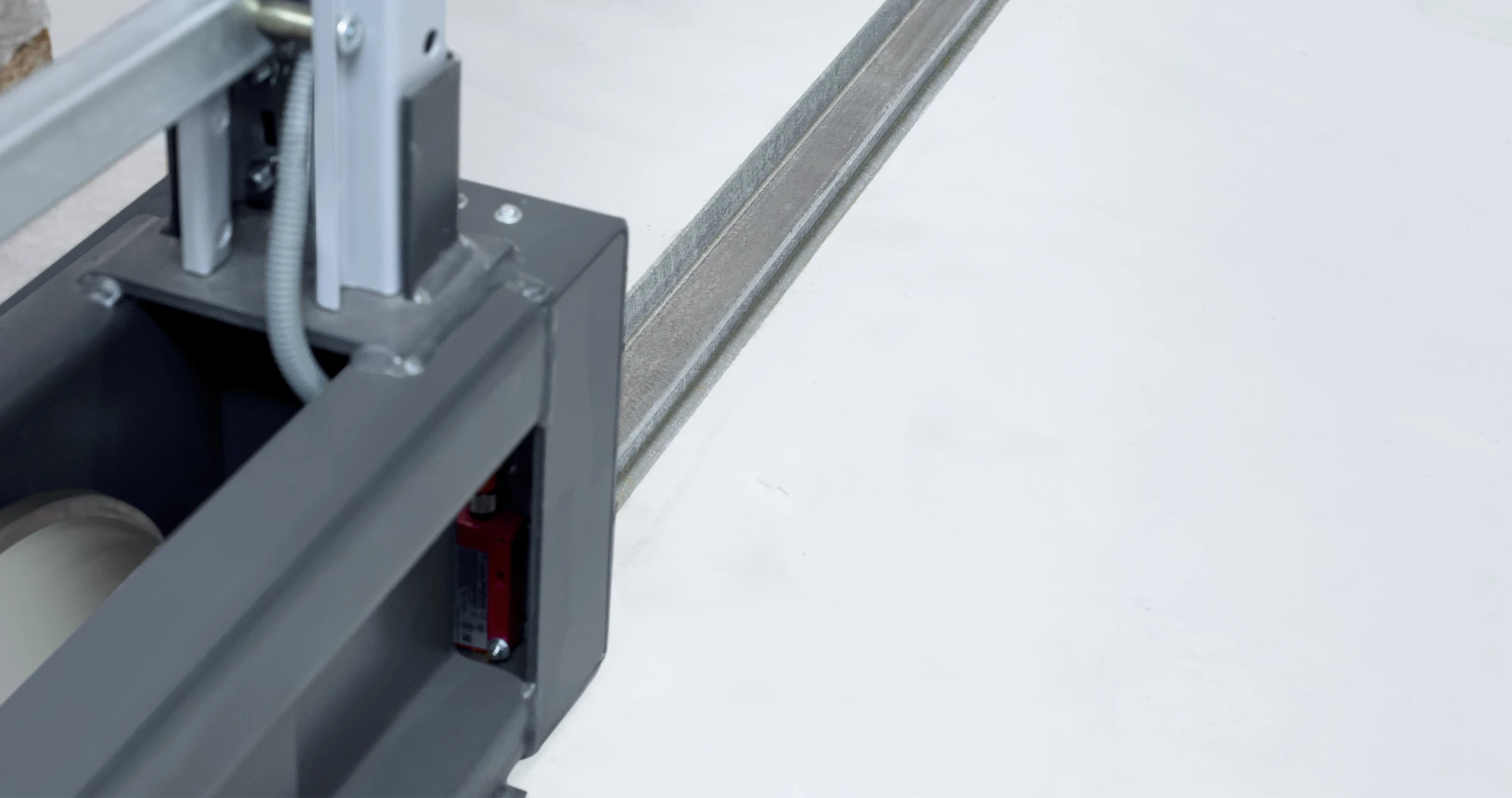

The carriages are operated by controls on the rack support, via remote control or automatically via an interface that is connected to a warehouse management master system. Light barriers are installed for pedestrian protection.

Mobile racks consist of the rack itself, a carriage, running and guide rails as well as control and safety equipment. Light barriers are installed for pedestrian protection.

The rack is usually a pallet or cantilever rack. Therefore long materials or different loads on pallets can be stored on the racks. The length of the dynamic racks and the number and heights of levels are individually adapted to your requirements. Then a suitable carriage, which is able to carry the desired loads, is selected. The carriages move on rails.

Rails

A mobile rack system requires rails in the floor on which the mobile racks can move. There are guide rails with grooves and smooth rails, the so-called running rails. The upper edge of these running and guide rails is at floor level. Because the floor is not yet cast in newly constructed buildings, it is often possible to install higher crane rails. The high crane rail can be installed inside the top flooring layer. The layer completely encloses the crane rail firmly anchoring it in the floor. In existing warehouses, flat rails can be installed in a cut groove or directly on the existing floor. Direct installations on the existing floor require building a new top flooring layer afterwards.

Carriages

The carriage is a central component of mobile rack systems. The racks are mounted to the carriage. The carriages are equipped with motors. These motors move the carriages on the rails along the floor.

There are two- or four-wheeled carriages, fitted with either smooth or guiding wheels. The design of the carriages depends on the planned load weights.

End face protection

The end face of the mobile rack is equipped with light barriers. The light barriers are used for entry/access control in operation.

If the light barriers of the end face protection are interrupted by a pedestrian or a truck while the mobile rack is moving, the system is automatically stopped. In addition, the system is equipped with emergency stop buttons.

The picture shows the relationship between shelf levels, lift heights, the required trucks and working aisle widths. The truck and the mobile rack are synchronised and planned in accordance with your requirements.

- Control: The controls are used to open a working aisle by moving the individual carriages.

- Remote control: The optional remote control allows to save walking distances and time by opening a working aisle from inside a truck.

- Carriage cover: The carriages are equipped with covers (chip board/grids) to protect accessible hazardous areas and to prevent accidents. In addition to chip boards, optional placement frames can be used, which increase the load capacities of the chip boards on the lowest carriage level.

- Rear wall mesh grids/security fences: Rear wall mesh grids are used to protect pedestrians. These components are attached to the back side of a rack or to the floor. Mesh grids prevent employees from being injured by pallets falling off the rack. Security fences ensure that the system can only be accessed through the entrances protected by light barriers.

A warehouse planned for efficiency guarantees high economic feasibility. Benefit from the professional consultation with our STILL experts right from the start of warehouse planning. Before you make a buying decision, we assist you in every aspect – from checking your warehouse design to discussing the planned workflows. There are many reasons why you should decide for STILL when buying a pallet shuttle rack:

- Many years of expertise: Close to our customers for more than 95 years.

- Partnership that you can rely on.

- Holistic premium concept – from consultation to service.

- Always close to you: 14 branches, 37 rental branches & 800 service technicians in Germany alone.

- A trained installation team ensures proper assembly of your pallet shuttle rack.