Diesel and LP Gas forklift truck RX 70 2.0 – 3.5 t

Performance meets efficiency

- Powerful, efficient and precise: STILL Performance System with perfectly coordinated components

- Complete control: the STILL Easy Control on-board computer –performance functions at the push of a button, relevant info at a glance

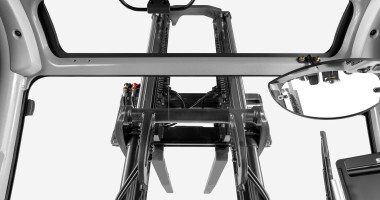

- Clear view ahead: optimal visibility thanks to the slim mast, large windows and thermoformed dashboard

Request to: RX 70 2.0 – 3.5 t

Please fill out the form below. We will get back to you as soon as possible.

Full speed ahead: the industrial engine with over 20 percent more power means that the RX 70-20/35 can move more goods to their destination even faster – and yet it remains impressively efficient! This is made possible by the STILL Performance System: perfectly coordinated components combine a powerful and efficient drive with precise and sensitive control. Every RX 70-20/35 is built to impress for years: durable material and compact design meet unmatched performance dynamics. The top performer has a multitude of strengths that are effectively adapted to every situation thanks to the intuitive operating elements.

What’s more, every detail of the comfortable driver’s cab has been carefully considered, from the large footwell through to the thermoformed dashboard for maximum visibility. The STILL Easy Control is the cockpit’s smart centrepiece. The smart on-board computer provides direct access to performance functions and displays relevant truck information at a glance. Reversing in tight spaces, frequent driving up and down ramps, changing operating conditions – with the RX 70-20/35 you have the load handling under control at all times, even in tough and challenging situations. Experience intelligent performance at its best!

Simply easy

- Intuitive handling: standard, easy-to-use operating concept across the whole RX product line

- Climb in, get comfortable and get going: spacious driver’s cab with adjustable steering column

- One glance or click is all you need: the STILL Easy Control on-board computer activates performance functions at the push of a button and displays all the relevant information at a glance

- Work made easier: a range of assistance functions make work easier and improve safety

Simply safe

- Perfect all-round view: large viewing window, also in the protective roof

- Good tracking and stability: outstanding driving stability when turning and a low centre of gravity

- Guided safety check: the truck is released after a display-guided function check

- Safe entry and exit: large non-slip steps that are also visible from above as well as grab handles on the protective roof

- Consistent drive power: every drive wheel is separately controlled and makes sure that the truck is always kept on track

Simply connected

- Digital Performance Boost: optional interface for integration into fleet management software, such as STILL neXXt fleet

- Flexible networking: the provision for MMS means that the truck can be integrated into every material flow management system with ease

Simply powerful

- Strong performance: powerful drive meets precise control

- Effective goods handling: travel speed of up to 21 km/h

- Agile performance: parallel operation makes it possible to drive and lift or tilt at the same time

- Flexible power control: electrically adjustable hydraulic pump

- The new STILL Performance System perfectly coordinates the entire system of all drive components and operating functions

- The powerful and quiet diesel-electric drive in hybrid technology ensures exceptional handling performance with low consumption, low noise emissions and minimised environmental impact

Simply flexible

- Flexible control options: mini-lever, Fingertip or Joystick 4Plus

- Safety and comfort in every situation: flexibly adjustable driving and lifting performance

- Perfectly tailored operating power: extensive equipment options for maximum performance in every application

Equipment options

Sharpening all senses: we can support you with our wide range of smart driver assistance systems and functions which will make your day-to-day work significantly easier. You will be able to drive in a safer, more comfortable, efficient and fatigue-free manner – in every driving situation.

Safety first: digital guided Pre-Shift Check

With the Pre-Shift Check in the on-board computer STILL Easy Control STILL achieves a new level of safety for the driver and the truck: before the start of each shift, or at user-defined intervals, the driver must confirm the operational capability of the truck via the on-board computer before he can put the truck into operation with all its functions.

The customer is free to choose the criteria of the safety check. In addition to the standard query, several individual queries can be stored in the display of the on-board computer. And if an answer is negative? The customer has all options.

For example, he can define in the system that the performance of the vehicle is automatically limited if a query shows a negative test result.

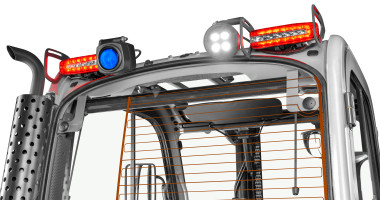

Learn moreThe visual warning system for fewer accidents

The blue warning light, STILL SafetyLight 4plus, significantly increases work safety in areas which are confusing or full of bends. The blue light spots are projected approx. 5 m in front of and behind the truck and warn people about the approaching truck to prevent impending collisions.

Perfect addition to the STILL SafetyLight

The STILL warning zone light projects two strips of light to the left and right of the forklift truck. The optional illumination equipment serves as a visual warning for pedestrians and other drivers in the vicinity by projecting luminescent strips on the hall floor at the sides of the forklift truck.

The STILL Warning Zone Light Plus projects a semi-circle around the rear of the truck. This also increases awareness of the truck and marks a typical danger zone when approaching. This reduces the risk of pedestrian injury.

The STILL Warning Zone Light and the STILL Warning Zone Light Plus therefore perfectly complement the STILL Safety Light, which projects a blue cone of light in the front of the truck in the direction of driving.

With the breathalyser, the driver has to carry out an alcohol breath test before they can operate the truck. The truck is only released once the test has been passed. The advantage of the test is that it is very difficult to manipulate the results and can help to prevent accidents. Thanks to interchangeable mouthpieces, it is hygienically safe.

The broadband alarm is an audible alarm that emits a broadband signal tone. Over longer distances, the tone is drowned out by ambient noise. However, in the immediate environment the noise and thus the source of danger are very easy to locate. This increases awareness of the truck and prevents accidents.

Bracket systems protect drivers thanks to their stable structure and assembly within the truck contour. We also offer fitting and retrofitting for trucks with a rear windscreen. This does not restrict the freedom of movement or the all-round visibility of the driver, nor does it make getting on and off the truck more difficult. The manual system can be opened and closed by hand. The automatic system is coupled with the hand brake or accelerator pedal, and closes the bracket as soon as the truck begins to move.

The protective grille roof is available in a low or high version, according to the height of the passageways. It protects the driver from falling loads.

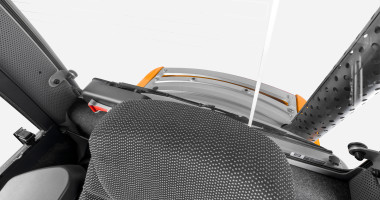

Owing to the EasyBelt, the seat belt is already diagonally taut over the driver's seat. When stepping aboard, the driver only needs to climb into the pre-tensed belt. The quick and convenient handling of the EasyBelt makes buckling up a breeze. How you benefit: Cost-effective addition to the belt which ensures that the driver is able to properly secure their seat belt without effort;

Enables quick seat belt fastening and unfastening, thus having a positive effect on productivity;

High comfort level within the driver's work space due to the quick and easy handling of the seat belt – resulting in a high acceptance level from forklift truck drivers;

Easy to retrofit – EasyBelt can easily be retrofitted onto your fleet's counterbalanced forklift trucks.

The innovative AI camera system recognises people and person-like objects in the rear area in real time. The driver receives a multi-stage warning on the HD camera image inside the truck. If a person falls below the defined warning area, the system automatically initiates a speed reduction.

- Innovative AI camera system

- Optional STOP function for person detection

- Recognition of persons and person-like objects

- Integrated loudspeaker to play warning sounds in real time

- Customisation of detection zones and warning mechanisms

- High HD resolution for greater detail

- Can be individually extended to additional cameras

- Maximum functionality in a slim and robust design

- Smooth operation even under extreme conditions: Operation even at -40°C to +85°C

Keeping the goods in place: the load backrest stabilises the transported goods at the fork carriage back so that they can be securely transported from A to B.

The Reversing Alarm Plus prevents collisions and personal injury. It is a 3D camera-based assistance system for rear monitoring, and also detects the presence of people and objects. A rear view image is displayed on the monitor, whereby the system reliably distinguishes between pedestrians and objects and triggers an appropriate response, such as emitting a warning signal or braking.

The rear warning device alerts the driver to objects and pedestrians behind the truck. It comprises a radar-based rear monitoring sensor for obstacle detection and a light indicator with signal tone. The reach and width of the monitoring area can be individually configured. The light indicator and signal tone warn the driver of a potential collision.

Buckled up? If not, the seat belt control ensures that the driving speed is automatically reduced. In cab trucks, the system only engages when the cab door is open.

A flashing, warning or rotating light increases safety at the warehouse and makes other employees working in the warehouse aware of the forklift truck via a flashing yellow light signal. If preferred, this can be set to only light up when reversing. The use of this light increases safety particularly in areas where hearing protection is required to be worn. The rotating light is available in various designs and can be mounted on or behind the overhead guard.

Access control perfectly integrated into the truck with different types of access authorisation for one or more trucks: with STILL Smart Portal you are free to choose the type of access authorisation for one or more trucks: chip, FleetManager card, your personal plant ID card or a PIN.

Thanks to the smart auto-logout function, the trucks are automatically deactivated after a freely selectable period of time – this also increases safety.

Digicode systems (PIN) are an easy way to prevent unauthorised use of the truck. The truck can be started up quickly and easily, simply by entering the PIN code. This allows the user to limit access authorisation to specific individuals or groups. It is possible to configure up to ten PIN codes.

More informationAutomatic speed adjustment for curves

The speed limiter controlled by steering angle reduces possible damage to goods by adapting to an appropriate cornering speed. This assistance function is available for various forklift trucks and warehouse technology devices, and regulates the driving speed automatically according to the steering angle. In other words, the driver doesn’t need to worry about speed when cornering. The truck automatically decelerates precisely as much as necessary for the operator to drive as safely but as quickly as possible.

Lifting movements that adapt to the load? Stable idea!

Whether it's an inexperienced operator, careless movements or a particularly heavy load - there are various reasons for abrupt movements of the lifting hydraulics, which can quickly lead to goods breakage or even personal or vehicle damage. Dynamic Load Control brings calm to the mast. Feel how the assistance system makes load handling better and smoother. It detects the current load as well as the current lift height and automatically adjusts the speed of the lifting hydraulics before anything falters. In the second of two expansion stages, Dynamic Load Control also takes the load's center of gravity into account. In this way, it increases stability and prevents the vehicle from tipping forward - even with small weights and large load centers. The graphic stability index also shows you at a glance how stable the vehicle is on the ground with the current load and lifting height.

Learn moreWith the help of the optional LED lift height sensor (standard on the FM-X), the lift height display ensures maximum precision from the very first millimetre. This means that operators always know the height of the fork tips and can navigate precisely to avoid touching the rack when picking up the pallet. The system works with a repeatability of less than +/- 5 mm and the lift height is permanently shown to the drivers on the display.

Learn moreThe ceiling sensor detects low ceiling heights and prompts the driver to reduce their speed in order to promote general work safety in the warehouse. It comprises an ultrasonic sensor on the roof of the truck, which detects ceilings up to a height of 20 m. Depending on the sensor signal, the maximum speed is controlled, whereby the standard speed is 6 km/h.

Who can use which forklift truck for which area of application? How fast may a certain driver travel in the industrial truck?

The solution: our smart driver profiles in STILL Smart Portal. This web-based application allows the features of the truck to be adapted to the operator’s requirements, such as a reduction in travel, lifting or tilting speed or automatic activation of the lights.

Overload excluded:

If the forklift can still handle this load? A question that can quickly lead to injuries, vehicle or goods damage. Fortunately, there is overload detection. The system monitors the weight of the load and any attachments and always gives you a safe and clear answer. What's more, if the total weight exceeds the rated capacity or the set maximum load, the system actively intervenes and reduces the lifting speed. If the threshold value is exceeded by more than 10 percent, the lifting function is completely blocked. This means that the driver, vehicle and goods are always optimally protected.

Learn more

Autostop before ground contact:

When forks hit the ground, it's not pleasant for the ears, the floor or the forklift. But on the other hand, would it not be very pleasant if this would not happen in the first place? That's exactly why we developed the electric fork wear protection for you. When the assistance system is activated, it ensures that the forks cannot touch the ground during lowering. Shortly before that, they stop automatically - exactly so that you can thread them perfectly into the pallet. Forks dragging on the ground due to accidental startup in the lowered state are also a thing of the past.

Learn more

The automatic parking brake is applied automatically or at the push of a button, and prevents the truck from rolling. The electrohydraulic spring-loaded brake locks whenever the truck stops.

Equipping forklift trucks with a fire extinguisher can help prevent the risk of fire. This should be clarified as part of the risk assessment. This enables fast and direct action in case of fire, thus preventing major damage.

Windows can be broken with the emergency hammer provided.

The fork camera prevents damage to goods, personal injury due to falling loads, and collisions with the shelving. The system is mounted on the inner side of the fork tips and improves the visibility of the load, particularly at large lift heights, as the camera view is displayed on the driver’s monitor.

Forks up, speed down:

More safety, less product breakage and ensuring proper vehicle use - these are the benefits offered by the Speed Reduction assistance system when the fork carriage is raised. As soon as the forks reach a height of 500 mm (or another defined threshold), the speed of the vehicle is automatically reduced. Even if a driver forgets that he should not drive with the load raised, the assistance system slows him down, guaranteeing safe handling of the load and vehicle.

Learn moreThe integrated horn is located on the handle to the rear of the overhead guard. The horn signal sounds at the push of a button. Thanks to this simple and ergonomic method of signalling, when reversing the driver can warn pedestrians in the area that the truck is approaching.

The camera systems for fork carriage, outer mast and rear offer improved visibility and thus help to prevent collisions with the warehouse infrastructure, as well as personal injury. The camera, which is attached to the truck according to its position, improves the driver’s vision of the environment by displaying an image on the driver’s monitor of everything that is captured by the camera in front and behind the truck.

The panoramic mirror, which can be mounted on the left or right side of the truck, improves visibility and reduces the size of the blind spot by expanding the field of vision. Drivers are able to get a quick overview of what’s behind them, allowing them to work more safely.

Downloads

The document provided for download is the updated version of the operating instructions for the standard truck. It does not include descriptions of customer options (Customer Option). For a concrete truck, please request the respective specific manual according to the serial number and the year of production from the STILL spare parts service.

| Model | Maximum capacity (kg) | Maximum lift height (mm) | Travel speed (km/h) |

|---|---|---|---|

| RX 70-20/600 | 2.000 | 7.390 | 21 |

| RX 70-20/600 T | 2.000 | 7.390 | 21 |

| RX 70-25 | 2.500 | 7.390 | 21 |

| RX 70-25/600 | 2.500 | 7.390 | 21 |

| RX 70-25T | 2.500 | 7.390 | 21 |

| RX 70-25T/600 | 2.500 | 7.390 | 21 |

| RX 70-30 | 3.000 | 7.390 | 21 |

| RX 70-30/600 | 3.000 | 7.390 | 21 |

| RX 70-30T | 3.000 | 7.390 | 21 |

| RX 70-30T/600 | 3.000 | 7.390 | 21 |

| RX 70-35 | 3.500 | 7.390 | 21 |

| RX 70-35T | 3.500 | 7.390 | 21 |