The way to your automated tugger train

How to make the changeover to automation in production logistics

Making automation tangible in your company is a complex endeavour that requires a high level of expertise in this area. Each automated tugger train solution implemented must be considered individually.

The answer to the question of automation requires foresight – the question to ask is this: "How do I want my processes to work in 5 or 10 year' time?" STILL helps you analyse your processes and identifies automation potentials.

How can you ensure that the high capital expenditure on a driverless transport system will have the desired effects?

The ticket to entering the internal transport logistics of the future includes seven key factors, which STILL’s team of experts will scrutinise together with the company.

7 key factors for the successful implementation of driverless transport systems (DTS):

- Holistic understanding of the project and concept planning with foresight

- Technical design/technical requirement

- Strong requirements specification as the technical basis for the project

- Agile project management

- Realistic schedule with milestones

- Integration of the DTS into the peripheral equipment vs. adaptation of the peripheral equipment to the use of the DTS

- Early integration of work safety, IT and production

We use our expertise to help you analyse your processes and identify automation potentials in order to set your company up for the future.

Our tasks include: initial consultation, review of cost-effectiveness and technical feasibility, concept planning, drafting of the requirements specification, review of the functional specification, project monitoring and support during acceptance.

Three key aspects need to be considered when planning a tugger train system customised to your specific needs:

- the standardisation of the processes and transport equipment

- the automation of the loading and unloading processes

- the increased flexibility of the system in relation to the modified transport requirements and faults

Our specialists in intralogistics consulting work together with you to answer the following question: What does your automation system ultimately have to achieve?

With our expertise, we support you in the analysis of your processes and identify automation potential to position your company for the future. You decide whether you would like to take advantage of our additional consulting services. The services are carried out by experienced STILL intralogistics experts.

The result: An individual requirements specification as the technical basis for your automation project, based on your requirements, which you can use for your invitation to tender.

Potential analysis:

- comprehensive process and data analysis on site

- determination of capacity and performance requirements

- analysis of the technical and economic feasibility of a DTS

The result is a transparent and informative representation of your material flow as well as a recommendation for your automation approach.

Concept preparation:

- development of a target concept in close collaboration with you

- proposals for layout and adaptations to the environment

- calculation of the expected truck requirements

- determination of budget prices

Preparation of the requirements specification:

- detailed project and process description (target concept)

- definition of requirements (incl. IT, safety, operational environment)

- Development of a functional requirements specification as the basis for implementation

Requirements analysis

Our offer for the joint preparation of the concept and requirements specification

We answer the following question together with you: What potential for automation can be uncovered in your warehouse and production logistics – and what does your automation system ultimately have to achieve?

Result: an individual requirements specification based on your needs, which you can use for your invitation to tender. The requirements specification is the technical basis for your automation concept.

Three aspects play a key role with regard to this question; they relate to the existing equipment and processes and the automation of existing solutions and processes.

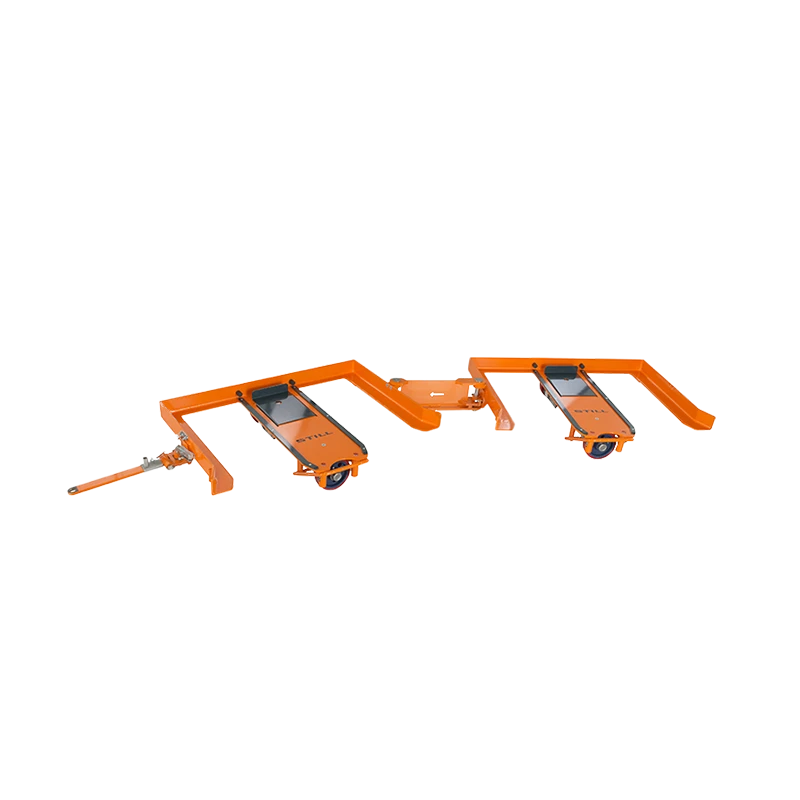

The use of existing equipment depends on the degree of automation. This then determines whether the existing equipment, apart from the tractor, can be retained. This becomes increasingly critical as the degree of automation increases and must be carefully examined as part of the consultation.

Modified activities generally also require modified processes. The specific adaptation of the processes must be individually clarified in the project. The level of automation is once again an important factor.

In principle, it is possible to automate existing solutions and/or processes. However, the replacement of a driver with a fully-automated truck alone does not lead to a change in terms of process-optimised lean production logistics.

In summary: The implementation of an individual fully-automated concept takes place in several steps in which aspects such as return on investment, the layout of existing production facilities as well as the increased control input play an important role.

Automatic travel with manual load handling offers far-reaching potential – between the production area and the supermarket, for example, as this reduces staff costs and increases the capacity utilisation. With automated load handling, it is possible to implement continuous tugger train supply to production even with heavy load carriers.

We use our expertise to help you analyse your processes and identify automation potentials in order to set your company up for the future.

Your very own requirements specification – step by step.

Rückruf vereinbaren

Glossary

Master controller

The master controller controls all of the trucks operating in the system. It helps the operator continuously optimise the operation. It connects a general host system, such as a warehouse control system (WCS) or a warehouse management system (WMS), and the deployed trucks.

Tugger train

Tugger trains are a means of transport for ground-level material transport. They are generally made up of a towing truck and one or more trailers, on which carriers are placed. Both the driving and load handling can be carried out either manually or partly or fully automatically.

Driverless transport systems

Driverless transport systems (DTS) are defined as follows according to VDI Guideline 2510: They consist of various components that have to work together in a precisely controlled and coordinated manner. These include a master controller, equipment for detecting and recording the location and position of the transport trucks, equipment for transmitting data to and from the trucks in the DTS, infrastructure and peripheral equipment (e.g. charging stations).

Dual use

Driverless transport systems with a dual-use function can be used in automatic mode as well as with manual control functions.