Autonomous mobile robots (AMR)

Autonomous horizontal transport of goods

Autonomous mobile robots such as STILL’s AXH iGo and ACH iGo series are small, manoeuvrable and intelligent underride vehicles that operate flexibly and proactively in complex warehouse structures. These can be used as a stand-alone solution or integrated into existing warehouse management and control systems to suit the customer’s requirements. Compared to classic automated warehouse solutions, AMRs can be integrated cost-effectively into existing environments and systems. Operating and maintenance costs are also comparatively low. To decide on the vehicle concept that best suits your specific needs, it is important to evaluate various criteria. These include, for example, the infrastructure, environment and volume of traffic in the warehouse, the need for buffer storage and the type of load, not to mention the cost implications. STILL’s experienced automation experts will support you in analysing your processes, evaluating the relevant criteria, selecting the right system as well as planning and implementing it. Our perfectly coordinated service concept, a comprehensive service network and the expert knowledge of specially trained service technicians ensure the availability of your system.

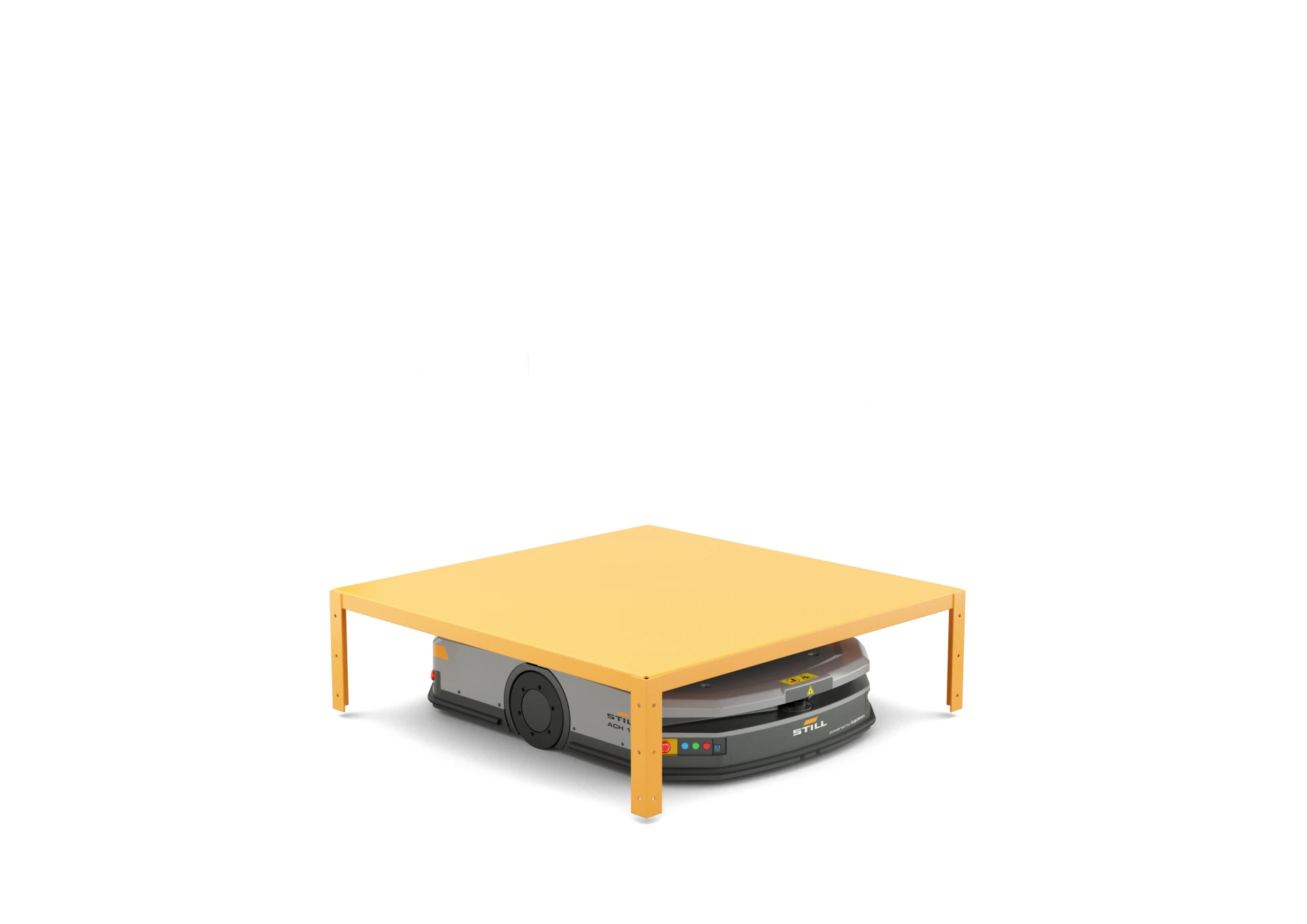

ACH iGo:

- High throughput with low space requirements

- Especially compact thanks to on-the-spot carrier rotation

- Easy to integrate into new, optimised process landscapes and in areas designed for the ACH

- Flexible transport of different carriers in tight spaces

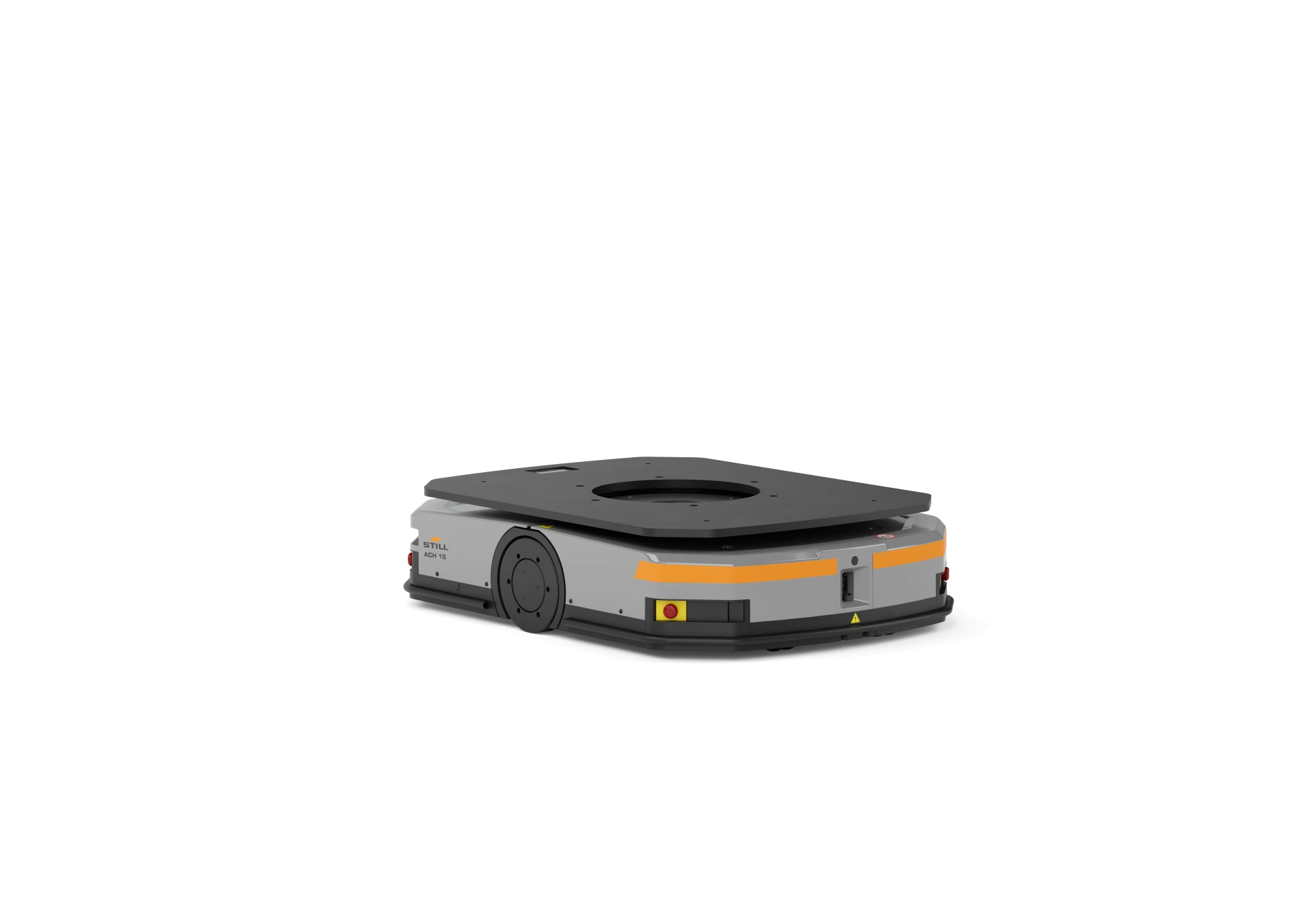

AXH iGo:

- Robust solution for dynamic mixed transport

- Safe load transport incl. flexible loading thanks to position detection via camera

- Efficient transport solution with obstacle circumnavigation for long distances

- Smart commissioning tools for individual hall layouts

Comparison AXH iGo versus ACH iGo

ACH iGo

- Commissioning: using QR code technology

- Navigation: Precise QR code navigation

- Transport distance: Short to medium distances

- Application: Flexible load handling with platforms/tables + pallet transport

- Capacities: 0.6 t / 1 t / 1.5 t

- Max. speed: 1.2 - 2.0 m/s

- 90° pick and drop times: Min. 35 secs

- Surrounding area when loading: Specifically defined during commissioning

- 90° loading (working aisle width Ast): Min. 1.4 m

AXH iGo

- Commissioning: Flexible + smart commissioning based on the specific environment

- Navigation: SLAM navigation and circumnavigation of obstacles

- Transport distance: Long distances

- Application: Flexible load handling with trolleys + pallet transport

- Capacities: 1 t

- Max. speed: 2.2 m/s

- 90° pick and drop times: Min. 45 secs

- Surrounding area when loading: Can be adjusted by the AXH, deviation of load placement by +/- 30 cm

- 90° loading (working aisle width Ast): Min. 2.8 m

Autonomous mobile robots (AMR) are already used in various industries today: e.g. parts supply for production, the automotive industry, logistics, medical manufacturing, clothing or electronics production, and e-commerce.

Goods transport with trolleys: When transporting goods using trolleys, the AXH iGo transports the entire unit from A to B. The innovative 3D camera ensures flexible lifting of the goods before they are loaded onto the AXH iGo as well as precise unloading at the desired destination.

Goods transport with pallets: When transporting goods using pallets, the AXH iGo picks up the pallet and its goods from a specified transfer station and transports it to its end station. Prior to unloading at the end station, the AXH iGo checks whether the transfer station is free for the goods to be unloaded using the innovative 3D camera.

Goods transport with grid box and adjustable rack system: When transporting goods using a grid box and individually adjustable rack system, the goods are flexibly loaded and transported to their destination. Depending on customer requirements, flexible transport options can be provided that also incorporate the use of a trolley.

Continuous development as a benchmark: Gradual automation using autonomous mobile robots.

U. I. LAPP GmbH recently opened its new logistics centre in Hanover. Since then, industrial trucks from STILL have been increasing the level of automation with their smart assistance systems – and thus also increasing safety and efficiency. Now the company is taking the next step in this direction. The company is testing an implementation of the STILL AXH autonomous mobile robot in the intralogistics processes of the new distribution centre, the medium-term goal being the gradual automation of the company’s intralogistics.

Read reference →

Goods transport via a loading platform (table): When transporting goods via a loading platform (table), the ACH iGo transports the entire unit from A to B. The goods are placed on the loading platform. The ACH iGo drives under the element, lifts it, transports it to its destination and deposits it there. If a conveyor trolley is used as the goods carrier, additional positioning measures may be required.

Goods transported directly on the vehicle: With direct goods transport, the goods carrier is transferred from the transfer station directly to the ACH iGo. The ACH iGo drives under the loaded station, lifts the pallet with its adapter plate and transports it to the destination. The station is refilled.

Transports individual carriers: Depending on the customer’s requirements, individual transport options (including a multi-level loading platform, conveyor trolleys or trolleys) are possible, e. g. for different carrier dimensions or transport orientation. If a conveyor trolley is used as the goods carrier, additional positioning measures may be required. Our STILL experts will implement a bespoke transport solution to suit your needs based on your specifications.

All STILL AMRs are equipped with lithium-ion batteries to ensure constantly high performance and availability thanks to simple interim charging. Multiple devices use the same fixed charging station to charge their batteries at different times. When it reaches a state of charge (SOC) of 30 % the vehicle autonomously initiates charging, then stops charging when it reaches an SOC of 90 %. This preserves the battery and ensures an optimum service life.

The ACH iGo charging device uses a connector. The vehicle reverses onto the charging station with the help of QR codes and docks with the connector.

The AXH iGo charging device has charging contacts on which the vehicle positions itself and aligns itself precisely.

Simply easy

- Space-saving and extremely agile (AXH iGo and in particular ACH iGo) and on-the-spot load carrier rotation (ACH iGo)

- Supports automatic battery charging (perfect for lifetime-optimised automatic charging)

- Low maintenance owing to lithium-ion battery

Simply powerful

- High handling performance thanks to a lifting capacity of up to 1,000 kg (AXH iGo)/1,500 kg (ACH iGo)

- Uses lithium-ion batteries that allow the vehicle to operate for an entire shift (up to 8 hours) on a full charge

- Short handling times and high throughput, particularly in areas with narrow aisles and short transport distances (ACH iGo)/over long distances in areas with standard-width aisles (AXH iGo)

- Efficient obstacle circumnavigation at a maximum driving speed of 2.2 m/s (AXH iGo)

Simply safe

- Meets the highest safety standards, including ISO-3691-4 compliance

- Maximum speed and cornering with the AXH thanks to two diagonally positioned safety scanners

- Maximum speed with the ACH iGo thanks to safety scanners in the direction of travel and mechanical bumpers for rotational movements such as turning 90° corners

- Always on the safe side owing to the multilevel, redundant safety system

- Suitable for use in mixed environments with operators or other vehicles

Simply flexible

- Scalable expansion possible as customer requirements increase

- Flexible use owing to the transport of various carriers and goods

- Excellent availability owing to lithium-ion battery

- Highly adaptable to hall layout thanks to smart commissioning tools and robust navigation technology (AXH iGo)

- Flexible and simple troubleshooting thanks to QR code navigation for the ACH and easy commissioning for the AXH iGo

Simply connected

- Simple integration into existing automation solutions and existing system landscapes via standardised IT interfaces

- Remote access to the vehicle possible via the control system

- Easy to integrate the AXH iGo into existing process landscapes and overlapping routes

- Easy to integrate the ACH iGo into new, optimised process landscapes and in separate areas

ACH 06 iGo

- load capacity: 600kg

- without an adapter platform

ACH 10 iGo

- load capacity: 1000kg

- with or without an adapter platform

AXH 10 iGo

- load capacity: 1000kg

- with or without an adapter platform

ACH 15 iGo

- load capacity: 1500kg

- with or without an adapter platform