Individual automation solutions according to your requirements

Automated guided vehicles implement the automated interaction of one or multiple different industrial trucks in order to perform transport tasks in the warehouse without a driver.

Different warehouse situations require individual solutions. Automated guided vehicles offer you a perfectly coordinated combination of different automated STILL series-production trucks and corresponding technology, including the installation of all components.

Analysis, planning, implementation – put your trust in automation that meets your needs and delivers maximum efficiency by selecting the best technologies for your requirements. Various types of navigation allow the trucks to move independently through the warehouse. In this way, you can always stay flexible because all automated series-produced trucks can also be operated manually in the worst-case scenario.

The quality of the automated guided vehicles series devices has been proven in numerous automation projects. Once the tailor-made automation solution has been implemented, a professional service model guarantees that your system is available at all times.

- Complete. Continuously automated material flow from goods receipt to outgoing deliveries with a complete range of automated STILL series-production trucks

- Intelligent. Truck control, traffic regulation, battery monitoring and effective fleet utilisation with the iGo software

- Organised. Effective cooperation from manually driven trucks with semi and fully-automated transport systems.

- Goal-oriented. Modern navigation technologies for secure, independent moving of trucks in the warehouse.

- Safe. Personal protection systems guarantee the utmost safety. Appropriate sensor technology ensures precise pallet detection.

- Flexible. Automated production trucks, which in special cases can also be operated manually.

- Needs-based. Standardised and scalable solutions for every automation requirement.

- Predictable. Short response times both in the design and quotation preparation stages, as well as in the implementation of projects.

Fully automated series-production trucks

LTX 50 iGo

The automated STILL LiftRunner tugger train solutions with the LTX 50 as a tractor can be used to realise a completely automated flow of goods right up to the production line, thus making the cycle-controlled supply of production lines even smarter and economical.

- For automatic horizontal transport

- Long-distance transport

- Production supply and disposal

- Up to 5t towing capacity

- Maximum standard speed: 1.7 m/s

- Production supply and disposal

- A variety of loading aids

- Dual operation possible if required

- 360° personal protection

EXV iGo

Whether in production supply or as an alternative in the pre-storage area – automated EXV high lift pallet trucks deliver the best services wherever they are used:

- For automatic loading and unloading in warehouses with wide aisles and for horizontal transport

- Use in wide-aisle and block warehouses

- Long-distance transport

- Production supply and disposal

- Load cycles up to heights of 3.8 m (depending on the application area)

- Maximum standard speed: 2 m/s

- A variety of loading aids

- Dual operation possible if required

- 360° personal protection

FM-X iGo

Automated FM-X reach trucks perform a wide range of tasks here:

- For automatic loading and unloading in warehouses with wide aisles and for horizontal transport

- Use in wide-aisle and block warehouses

- Feeding operations from one-way shelving all the way up to fully automatic shuttle systems

- Long-distance transport

- Load cycles up to heights of 10 m

- Maximum standard speed: 1.7 m/s

- A variety of loading aids

- Dual operation possible if required

- 360° personal protection

MX-X iGo

In narrow aisles, automated MX-X very narrow aisle trucks come into their own:

- For automatic loading and unloading in high rack warehouses with narrow aisles

- Use in narrow aisle warehouses

- Inductive or mechanical guidance

- Swivel traverse fork or telescopic fork

- Load cycles up to heights of 14 metres

- Maximum standard speed: 2 m/s inductive guidance, 3 m/s mechanical guidance

- A variety of loading aids

- Dual operation possible if required

- 360° personal protection

AXV 12 iGo

The automated pallet truck is so compact that it can handle even the tightest of spaces. The AXV iGo is also second to none when it comes to cost efficiency. When it comes to cost efficiency, there is no beating the AXV iGo

- Thanks to its working aisle width (branch) of just 2,480 mm, the AXV iGo can even fit in places where previously only manual vehicles could be used

- Incoming and outgoing goods

- Road transportation

- Supply and disposal of production

- Load cycles up to 1.8 m high (depending on the application)

- Maximum standard speed: 2 m/s

- Various loading aids

- Control with controller possible if required

- 360° personal protection

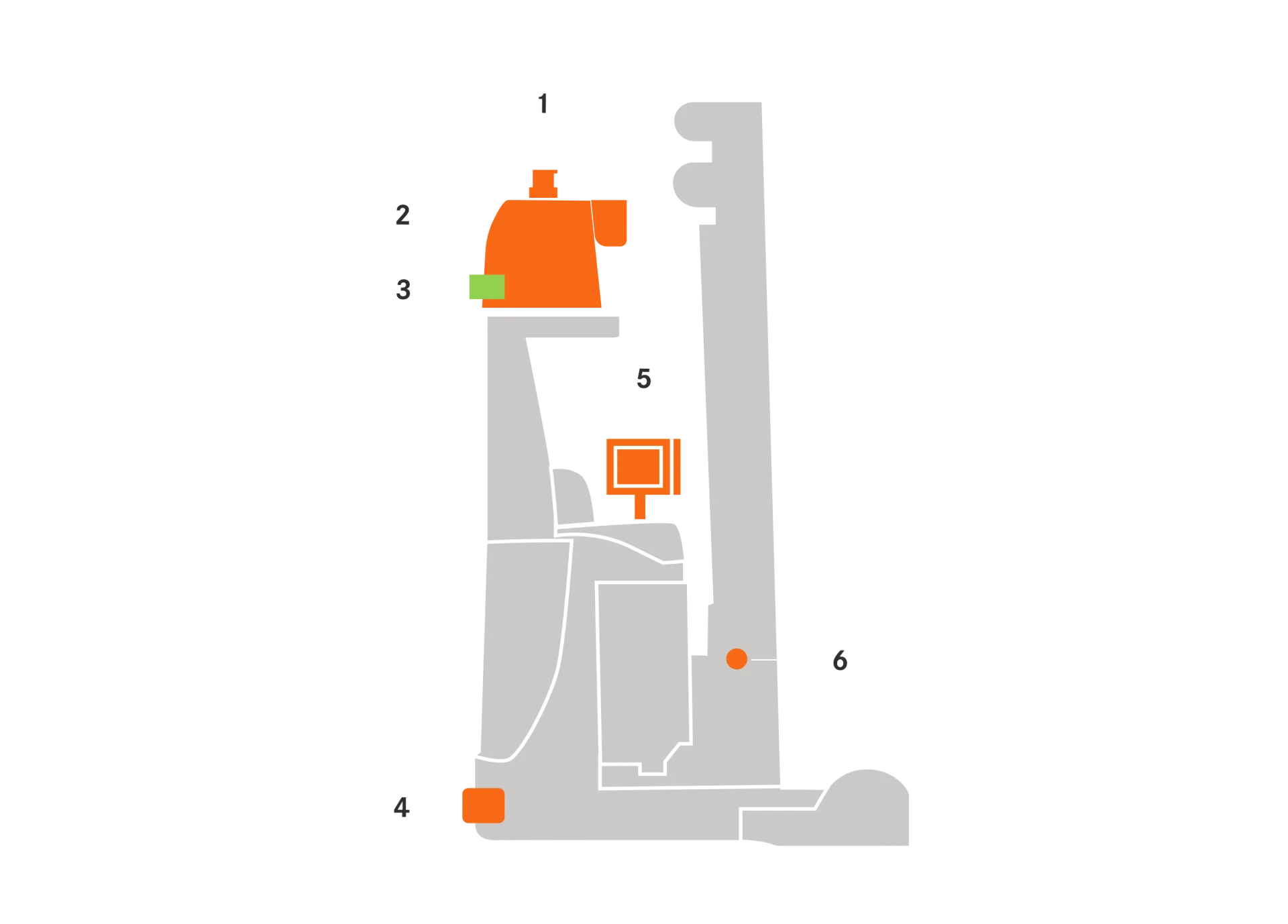

Automation kits with identical components, controls and interfaces turn a new series-produced truck into an AGV in no time at all.

1. Laser scanner

Truck navigation

2. Automation box

The steering unit receives driving instructions from the control system

3. Indicator lights

Indication of truck movements

4. Safety laser scanner

360-degree truck monitoring and personal protection

5. User interface

With screen or touchscreen

6. Emergency stop button

Lift mast and screen

We use our expertise to help you analyse your processes and identify automation potentials in order to set your company up for the future. You decide whether you would like to take advantage of our additional consulting services. The services are carried out by experienced STILL intralogistics experts and include the following steps in detail:

1. Data acquisition

Once the warehouse has been inspected, we receive a transparent overview of the existing material flow.

2. Analysis

Automation potentials are determined based on process and transport data, as is the technical and economic feasibility of different automation variants.

3. Guidance

You will be provided with individual guidance based on our years of expertise in the sector and on your financial key figures.

4. Concept and requirements

We develop a concept that gives you a clear indication of the added value you can expect. We establish a functional requirement as the basis for implementing your individual solution.

Tarkett

"The expected savings have also come to fruition," says Van Trijen. In addition, reliability has also increased thanks to the automation. There are fewer errors, and processes are running in a more efficient manner – "essential optimisations to remain the leader in a highly competitive market," says the Supply Chain Manager.

Van Trijen, Supply Chain Manager Tarkett

Read the customer example in full →

Audi

"The project is going very well. The reach trucks are recognizing all containers correctly and the IT interfaces are keeping the automated trucks continuously supplied with tasks,” Meier says. "We’ve been able to achieve the specified performance for both trucks every day, and at times we’ve even surpassed it."

Stefan Meier, logistics planner at Audi

Read the customer example in full →

CASA

"All of our logistics activities will be merged into a new, largely automated European distribution centre."

Bart Dauwen, Warehouse Manager, CASA International

Read the customer example in full →

Kuraray Trosifol

“We pitched our project to many well-known suppliers of driverless transport systems and complete solutions. In the end, there were only three who had the confidence to take it on, and ultimately STILL was the only contractor able to implement the complete concept in the very tight timeframe of only nine weeks,”

Manfred Kania, Head of Logistics, Kuraray Trosifol

Read the customer example in full →